Tel: +86-15060010188 E-mail: baochuangmachine@163.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

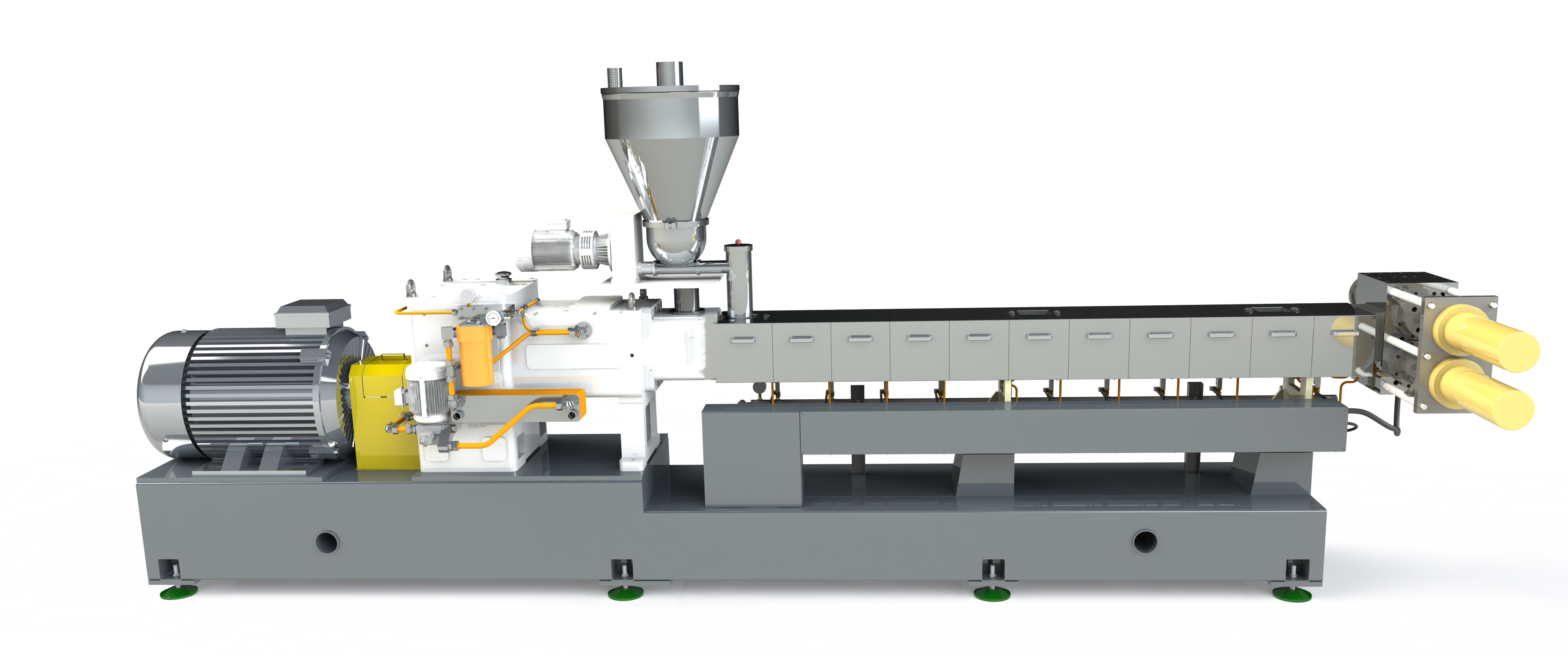

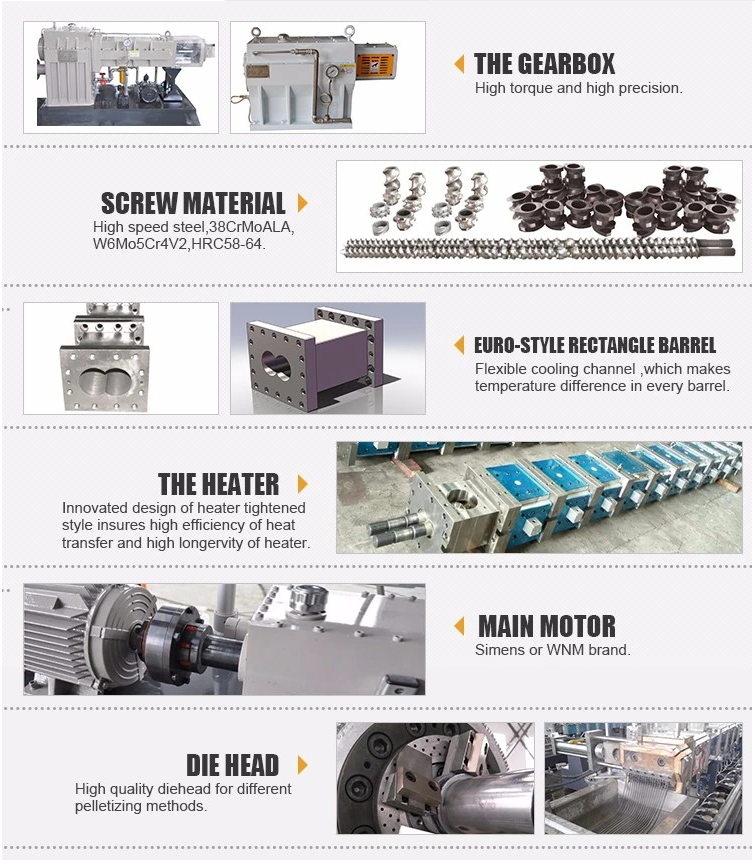

Machine Descriptions

Plastic Twin Screw Extruder Granules Making Machine. It is suitable for most polymer compounding production, which features simple structure,easy operation and convenient maintenance. The application of pellets can be thermoforming, sheet extrusion, injection molding and film blowing etc.

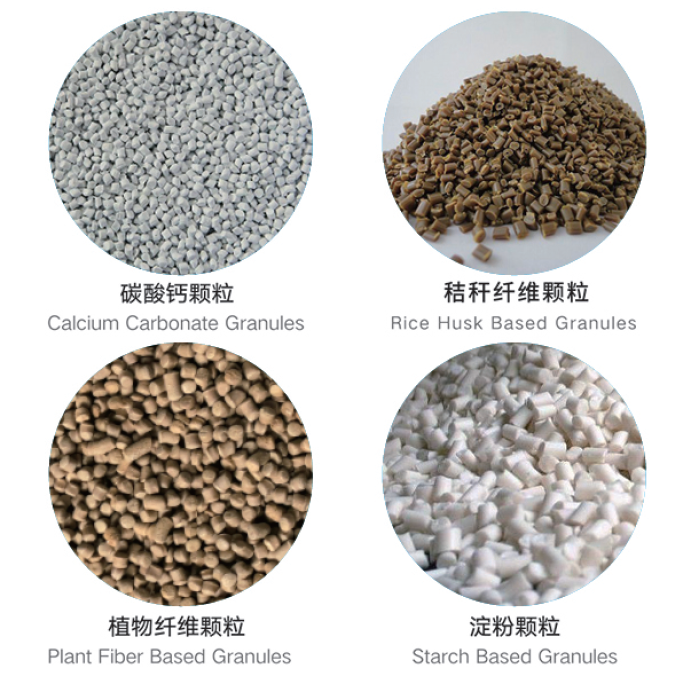

Full formula and entire technological process provided with machine line freely for manufacturing calcium carbonate filling pellets, rice husk based pellets, starch based pellets, biodegradable filling pellets, plant fiber based pellets etc.

|  |

Machine Specification:

300-500 High Speed Mixer | |||

Hot Mixer | Cold Mixer | ||

Total Volume(L) | 300 | Total Volume(L) | 500 |

Effective Volume(L) | 175 | Effective Volume(L) | 320 |

Capacity(kg) | 100 | Capacity(kg) | 100 |

Mixing Duration(min) | 8-12 | Coling Duration | 8-12 |

Output(h/kg) | 200-400 | Output(h/kg) | 200-400 |

Main Spindle speed(r/min) | 0-950 | Main Spindle speed(r/min) | 80 |

Heating Method | Oil Heating | Material Cooling Temperature | Less than 40 |

Material Temperature(C) | 140 | Cooling Medium | Water |

Discharge Compressed Air(Mpa) | 0.39-0.49 | Cooling Medium Pressure(Mpa) | 0.1 |

Temperature Control Methods | Automatic | Temperature of cooling water(C) | 15-20 |

Discharging Method | Pneumatics | Temperature Control Methods | Automatic |

Motor Power | 55KW | Discharging Method | Pneumatics |

Control | PLC | Motor Power | 11KW |

|  |

BC-65B Twin Screws Pellets Making Machine Line | |||

L/D | 48:1 | Diameter of Barrel | 63mm |

Gear Box | Type B | Feeder Motor | 1.5KW |

Screw Material | W6Mo5Cr4V2 | Fedder Capacity | 150L |

Screw Diameter | 62.4mm | Cooling Method | Fan Cooling |

Main Motor | 90KW | Conveyor Length | 18-20m |

Motor Rated Speed | 1480 R / PM | Power Supply | 380V3P50HZ(Adjustable) |

Screw speed | 500R / PM | Hourly Output Capacity | 300-450kg/hour |

Rated Power | 150kw | Machine Diamension | 23000*1100*2200mm |

Actual Power | About 100kwh | Weight of Machine | 6 Ton |

Finished Products

Packing And Delivery

Tests Report

|  |  |

|  |  |