Tel: +86-15060010188 E-mail: baochuangmachine@163.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Machine Advantages

1.Low Machinery Investment: Each line comes with all associate equipment that clients need to produce products: sheet extruding machine, forming machine, fully automatic hydraulic punching machine, mixer, smash machine, one set of customized mold and punching knife.

2.Low Energy Consumption: The sheet extruding machine produces sheet directly to product forming and punching.No secondary heating requires.

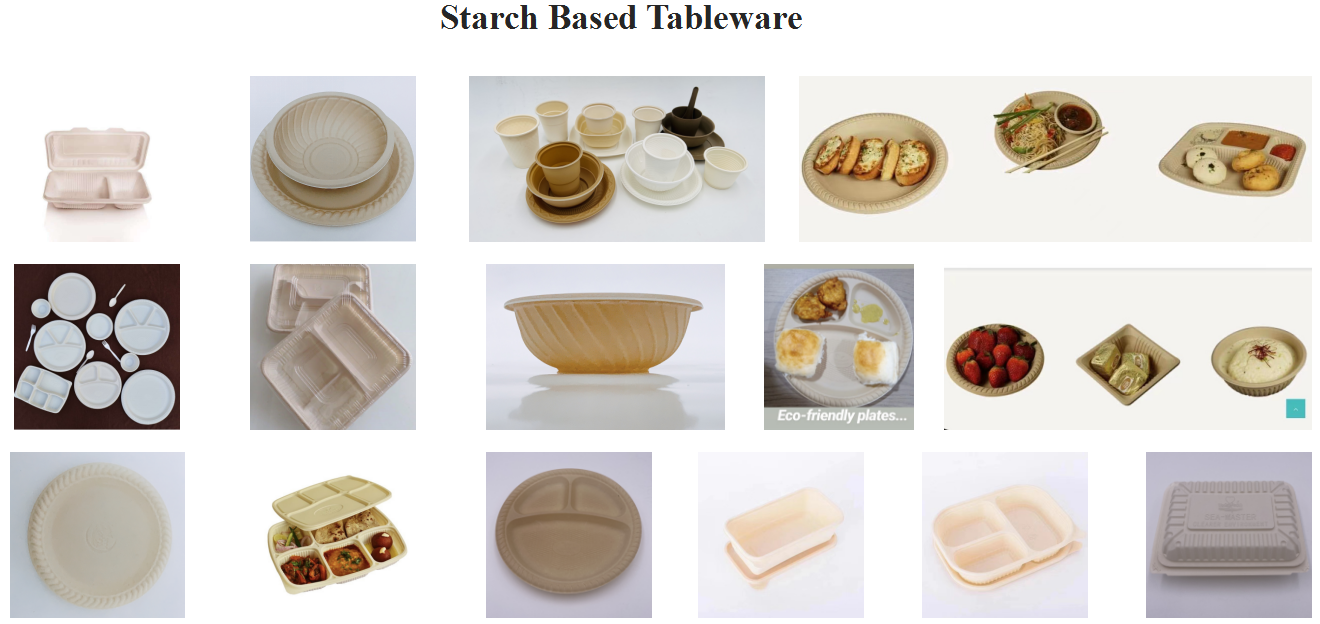

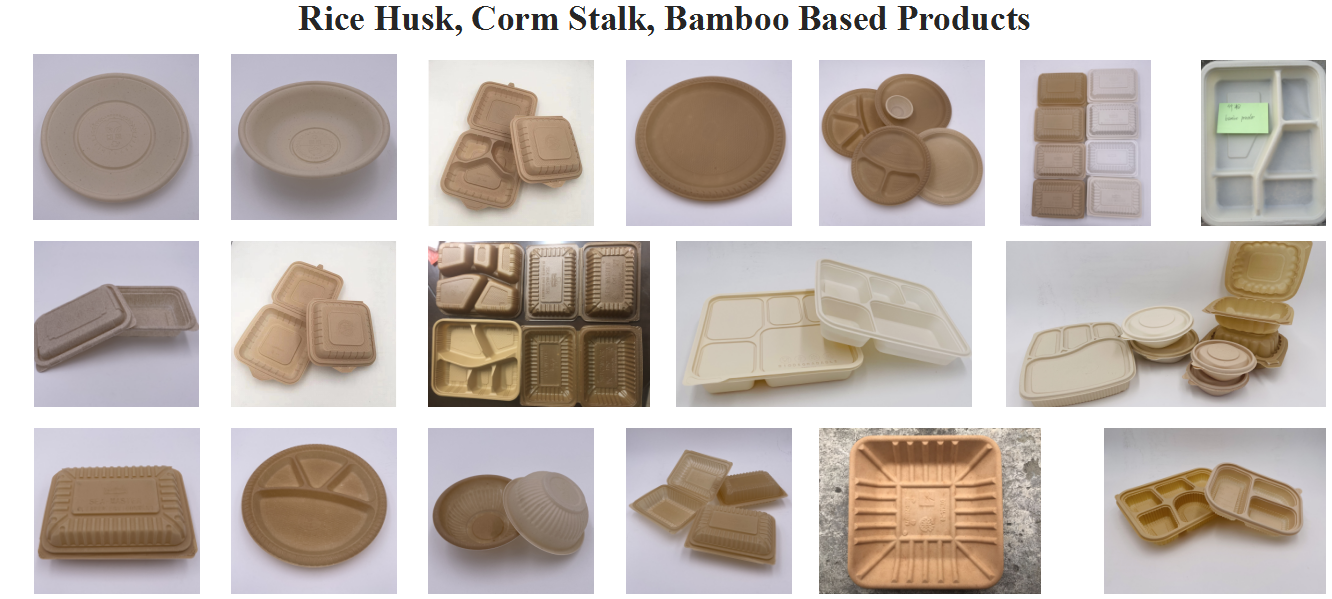

3.Adapt Multi Material: PP with calcium, rice husk, bamboo, talcium, starch, straw, PS, bamboo and other plant fiber.

4.Adapt Plastic Free Material such as PLA, PBAT or 100% biodegradable material.

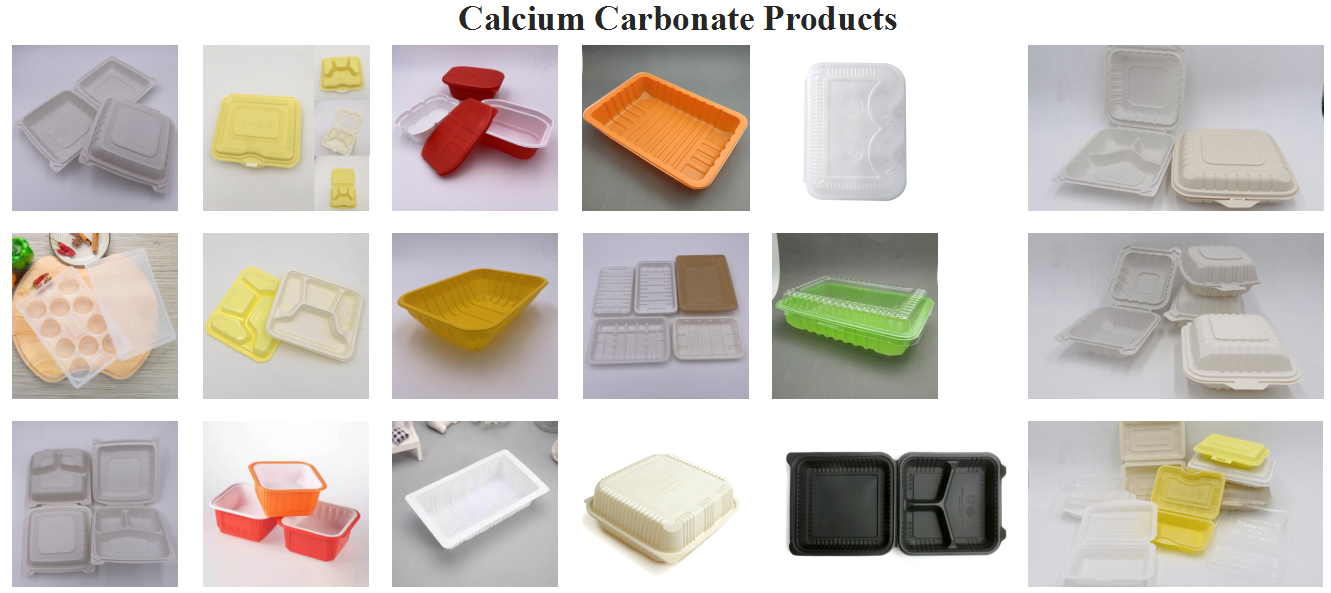

5.Multi Application: By changing mold, the machine line is able to produce lunch box, food container, clamshell box, market tray, food tray, bowl, plate etc. All mold can be customized according to clients needs.

6.High Automation and Easy Operation: Two workers are able to operate the full line each shift. One worker for packing and one for side material re-usage.

7.No material wastage: Side material can be smashed and re-mixed to be used again. There is no material wastage, no gas pollution and no water pollution during production process.

8.Durable and Reliable: The machine line is able to be running 24/7 without problem. Only Require basic maintenance.

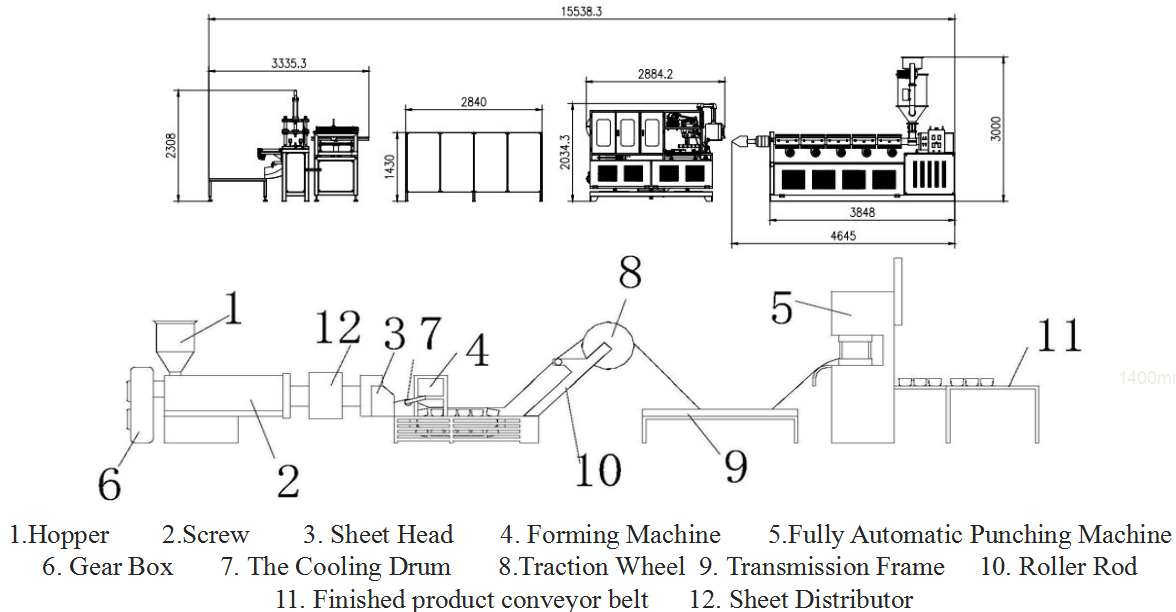

Machine Line Structure Drawing

Machine Specification

| 90B Sheet Extruder | ||

| Screw 1 | Alloy 90 |

Screw Ratio | 1:33 | |

Motor 1(kw) | 37 | |

Sheet Extrusion Method | One Layer, B | |

Sheet Head Size(mm) | L=1000 | |

Max Shaping Area(mm) | (750-800)×350 | |

Extrusion Output(kg/h) | 130-150 | |

Power Consumption (kw/h) | 30-35 | |

105-65ABA Sheet Extruder | ||

| Screw 1 | Alloy 105 |

Screw 2 | Alloy 65 | |

Screw Ratio | 1:33 | |

Motor 1(kw) | 55 | |

Motor 2(kw) | 18.5 | |

Sheet Extrusion Method | Three Layer, ABA | |

Sheet Head Size(mm) | L=1300 | |

Max Shaping Area(mm) | (950-1000)×350 | |

Extrusion Output(kg/h) | 270-300 | |

Power Consumption (kw/h) | 55-60 | |

90-80-65ABA Sheet Extruder | ||

| Screw 1 | Alloy 90 |

Screw 2 | Alloy 80 | |

Screw 3 | Alloy 65 | |

Screw Ratio | 1:33 | |

Motor 1(kw) | 37 | |

Motor 2(kw) | 22 | |

Motor 3(kw) | 18.5 | |

Sheet Extrusion Method | Four Layer, ABCA | |

Sheet Head Size(mm) | L=1300 | |

Max Shaping Area(mm) | (950-1000)×350 | |

Extrusion Output(kg/h) | 290-320 | |

Power Consumption (kw/h) | 60-65 | |

Servo Type Forming Machine | ||

| Product Thickness Range | 0.2-2.2mm |

Max shaping depth | 80mm | |

Traction Wheel Servo Motor | 0.6kw | |

Towing Chain Servo Motor | 1.5kw | |

Horizontal Axis Servo Motor | 0.4kw | |

Vertical Axis Servo Motor | 0.4kw | |

PLC | XDH-30A16L-E | |

Touch Screen | TGA63S-ET | |

Pumping Speed | 80m3/h | |

Pressure Of Air Source | 0.5~0.7Mpa | |

Cooling Method | Fan Cooling | |

Vacuum Pump | 100L | |

Hydraulic Punching Machine | ||

| Punching Speed | ≤45 Times/min |

Controller | PLC touch Screen | |

Double Servo | ||

Side Material Conveyor | 370W+Turbine Reducer | |

Product Conveyor | 370W+Turbine Reducer | |

Total Power | 7.5-9.5kw | |

Motor Load Ratio | 70% | |

Jacking Servo Motor | 0.75kw | |

Forwarding Servo | 0.4kw | |

Stacking Servo Motor | 0.75kw | |

Material That Machine Adapts

Finished Products

Machine Detail

|  |

| 105-65ABA Sheet Extruder | ABCA Sheet Distributor |

|  |

| Servo Type Forming Machine | Servo Type Forming Machine |

|  |

| Customized Food Tray Mold | Customized Clamshell Box Telfon Coating Mold |

|  |

| Fully Automatic Punching Machine | Fully Automatic Punching Machine |

Packing And Delivery

Tests Report

|  |  |

|  |  |